Plasma & Flame CNC Cutting Machines

MPL-X

MPL-X Series CNC plasma cutter is configured with heavy-duty components to deliver decades of unmatched cutting performance. This CNC plasma machine is designed for customers who require a unitized industrial quality plasma table.

Mpl X has a unique cutting table design. MPL-X Series plasma machines coming with PC based CNC control, heavy-wall steel frame and gantry beam, precision ground linear rails on both the X & Y axis, powerful AC servo motors and low back-lash planetary gear boxes. The gantry beam and cross axis carriage ride on precision ground linear tracks to deliver premium motion control and accuracy

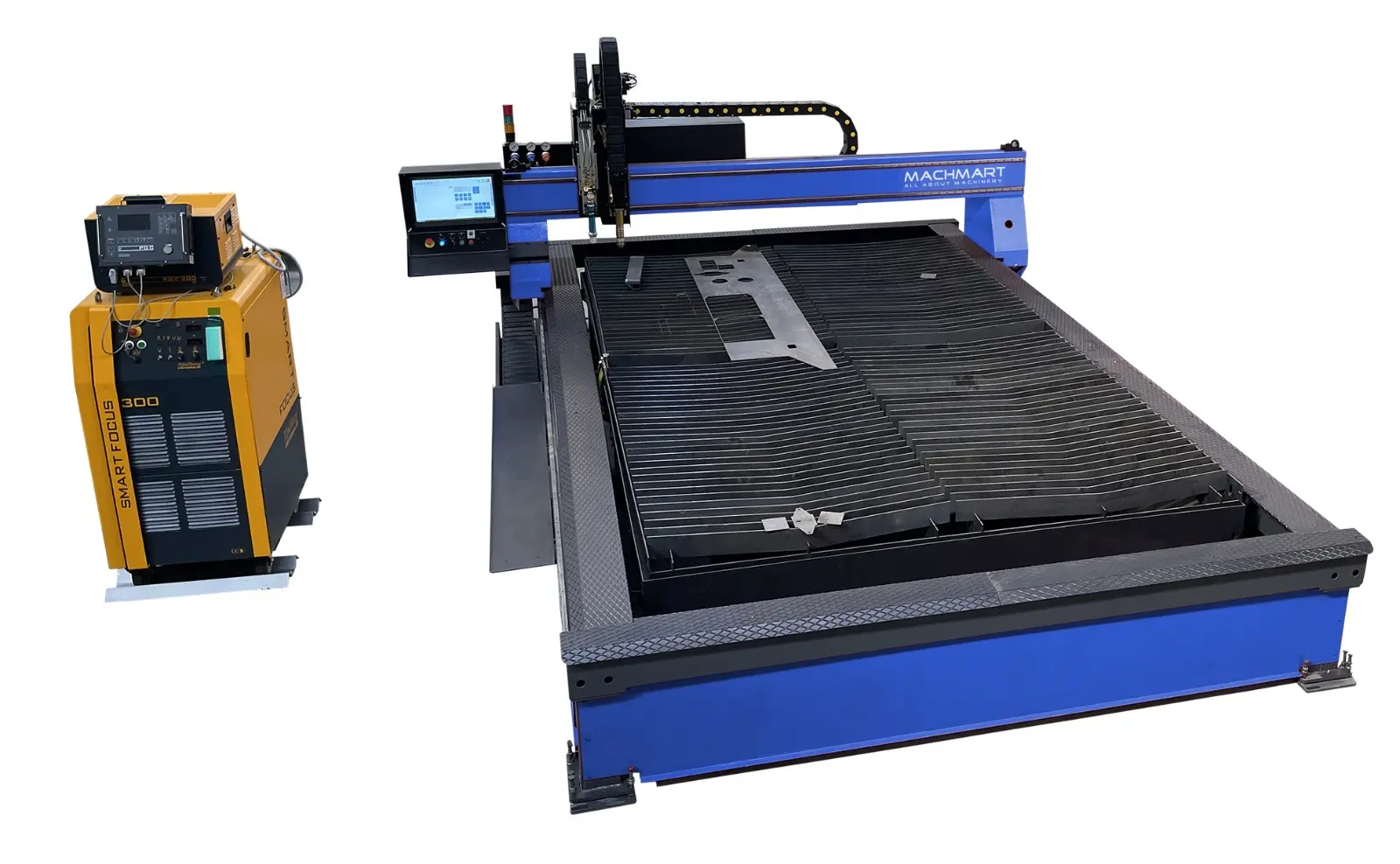

MPL-X ALFA

MPL-X Series CNC plasma cutter is configured with heavy-duty components to deliver decades of unmatched cutting performance. This CNC plasma machine is designed for customers who require a unitized industrial quality plasma table.

MPL-X Series plasma machines coming with PC based CNC control, heavy-wall steel frame and gantry beam, precision ground linear rails on both the X & Y axis, powerful AC servo motors and low back-lash planetary gear boxes. The gantry beam and cross axis carriage ride on precision ground linear tracks to deliver premium motion control and accuracy.

MPL-XT Eco

MPL XT that compact cutting machine is integrated plate and pipe cutting unit which can be installed and operated quickly and easily. Are you looking for an economical machine which gives full power in a small area?

MPL-XT Eco is the economical and robust machine for simple plasma cuts, oxyfuel cuts or both combined also pipe cutting unit can be added. All solutions in one compact monoblock eco cutting machine. XT-ECO can cut pipe 40 mm up to 400 mm in diameter.

MPL-Pipe Master

The Pipe Master series offers a wide range of pipe and profile cutting possibilities for various industrial applications in offshore, lifting and agricultural equipment, pipelines, power plant and steel constructions or shipbuilding. Modular design of the machine allows to meet unique pipe fabrication needs and thus become a valid part of your production facility.

Pipe master machines enable a wide range of pipe-based applications including trimming, cutting of various openings for multiple pipe and profile intersections or connections, weld edge preparation as well as marking.

The machine can be supplied as a fully automated workplace with automatic loading, feeding, unloading and sorting of pipes and profiles. Optionally, Pipe master can also be fitted with an additional cutting area for smaller domes. The modular design of the Pipe master series also allows to extend the machine with a customized pipe and profile sorting system tailored to your production layout. Fully automated pipe sorting is integrated with the pipe unloading area of the machine and configured with respect to the length of cut pipes and layout of the unloading positions to ensure the best sorting efficiency.